Getting more out of virtual testing for certification

In more and more industrial products, virtual testing involves the use of computer simulations to substitute physical certification tests.

Thanks to improvements to the versatility and power of commercial finite element analysis software, as well as the development of more realistic material and damage models, entire certification test campaigns can now be virtualised. This technology allows for more flexibility in product design, and faster certification, while simultaneously meeting, product and safety standards, as for example the strict requirements of aviation authorities.

Virtual testing has been used in the production of many important aircraft models, including the Airbus A380, A440M and A350 and the Boeing 777 and 787.

Applus+ Laboratories Absolute Accuracy methodology improves accuracy in virtual testing & speeds up certification.

Virtual testing isn’t without its problems, however. For virtual testing to be useful in a certification process, the test model used must be validated by correlating the outputs of the simulation with experimental laboratory data, in order to prove the model is suitably reliable and predictable for a test campaign. Moreover, in order for this experimental test to be truly representative of the virtual model, it is important to carefully observe the boundary conditions and restrictions imposed in the experimental setup. For smaller components, it is relatively easy to precisely control the way the part is constrained during the test, the quality of the test part, the rigidity of the tooling, and the positioning of the test sample. Most of these parameters are well defined in international standards.

However, when carrying out non-standardised tests, particularly on larger parts, with more complex load configurations, ensuring the right test conditions becomes much more challenging. Difficulties often arise in more complex test campaigns: usually, specimens are the first prototypes and because of this, they are more likely to have unexpected defects; large tooling setups are inherently more complex and less accurate, and constraints do not always behave as expected. For these reasons, precisely controlling and monitoring the load distribution and real boundary conditions of the part is more difficult.

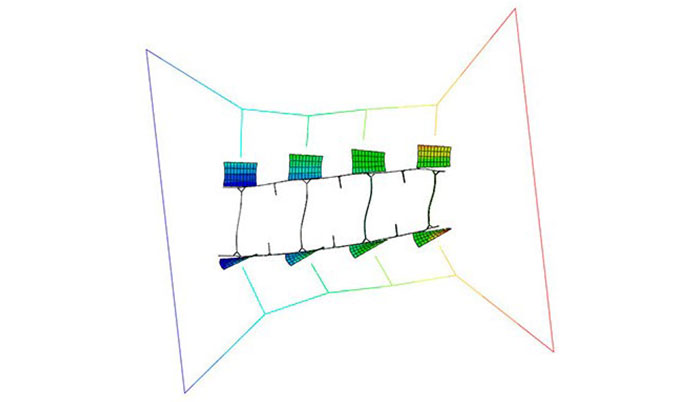

Example of a tooling that materializes a boundary condition and its mathematical simplification.

Test performed to evaluate the mechanical performance of a tool.

Example of a simulation based on experimental measurements.

Measurements of a boundary condition with an optical system (Digital Image Correlation) at Applus Laboratories.

This is where the Applus+ Laboratories Absolute Accuracy methodology comes in. Absolute Accuracy allows engineers to identify and monitor the real test setup and specimen geometry to better correlate a finite element model with an experimental test scenario, allowing a certain level of deviation from the ideal test conditions.

To apply the Absolute Accuracy methodology, Applus+ Laboratories carries out an exhaustive measurement of the initial conditions for the test (particularly the geometric deviations in the tooling and the test structure), and designs the tooling for load introduction and constraints, and so that they are more sensitive and can be instrumented. As a result of this more extensive instrumentation, it is possible to measure deviations in the behaviour of the test tooling, compared with theoretical ideal conditions. The deviations measured can then be implemented in the virtual model to replicate the real test conditions applied in the experimental test.

Using this information, Applus+ Laboratories adds crucial information helping to better compare experimental data and the virtual model, providing a more accurate model validation. This more reliable model can then be used for a Virtual Testing campaign that generates results that are more realistic.

Thanks to the Absolute Accuracy methodology, developed by Applus+ Laboratories over the last 2 years, the models used for virtual testing can be compared with well-defined and equivalent experimental data. This methodology allows for more realistic virtual models, improving their reliability. The resulting Absolute Accurate models are an excellent tool to speed up the certification process for complex structures, as required in the Aeronautical industry.

This methodology resulted from the development of the ABSOLUTE project funded by the Spanish Ministry of Economy and Competitiveness as part of the “Social Challenges” programme and was co-funded by the EU’s European Regional Development Fund.